The heart of any industrial embedded computing solution is the mainboard used as its basis. The application lifecycle is often longer than the lifecycle of some of the components used in the embedded computer. Processor, chip set and mainboard lifecycles can vary significantly based on the fact if they are specified for commercial or industrial use. We will take a look and explain the differences between both. Afterwards, we will explore how the usage of modular solutions based on a COM (Computer On Module) can extend product lifecycles even when chip manufacturers set critical components to end-of-life status:

Commercial vs. Industrial Lifecycle Expectations

Users of commercial mainboards are often concerned with performance over continuity of hardware implementation. As long as performance specifications are maintained or improved, the actual hardware used in the solution is of low consequence. It is not uncommon for commercial PCs of the same model to have different hardware components in them with only an invisible revision change maintained at the device manufacturer. This philosophy is much different in the world of industrial computing solutions. While the performance still plays an important role, the importance of maintaining the same hardware implementation is crucial. Industrial solutions often have rigorous safety, reliability and environmental tests that are tied to the specific hardware configuration. Changes in hardware will result in added costs and development resources to manage. Lifecycle of components used in industrial embedded computing solutions is critical to controlling costs and maintaining product in the field as a result.

Industrial Product Lifecycles

Most manufacturers of chips for industrial application recognize the importance of committing to a long lifecycle. Average lifecycles of such chips are about seven to fifteen years depending on manufacturer and popularity. When new generations of chips arrive, they often bring enough change that a new mainboard must be developed to support and socket the new chip. This can spell disaster for users of the solution dependent on that mainboard because the industrial solution may be in implementation for far longer than the hardware it depends on.

COM Based Solutions Have Lifecycle Advantages

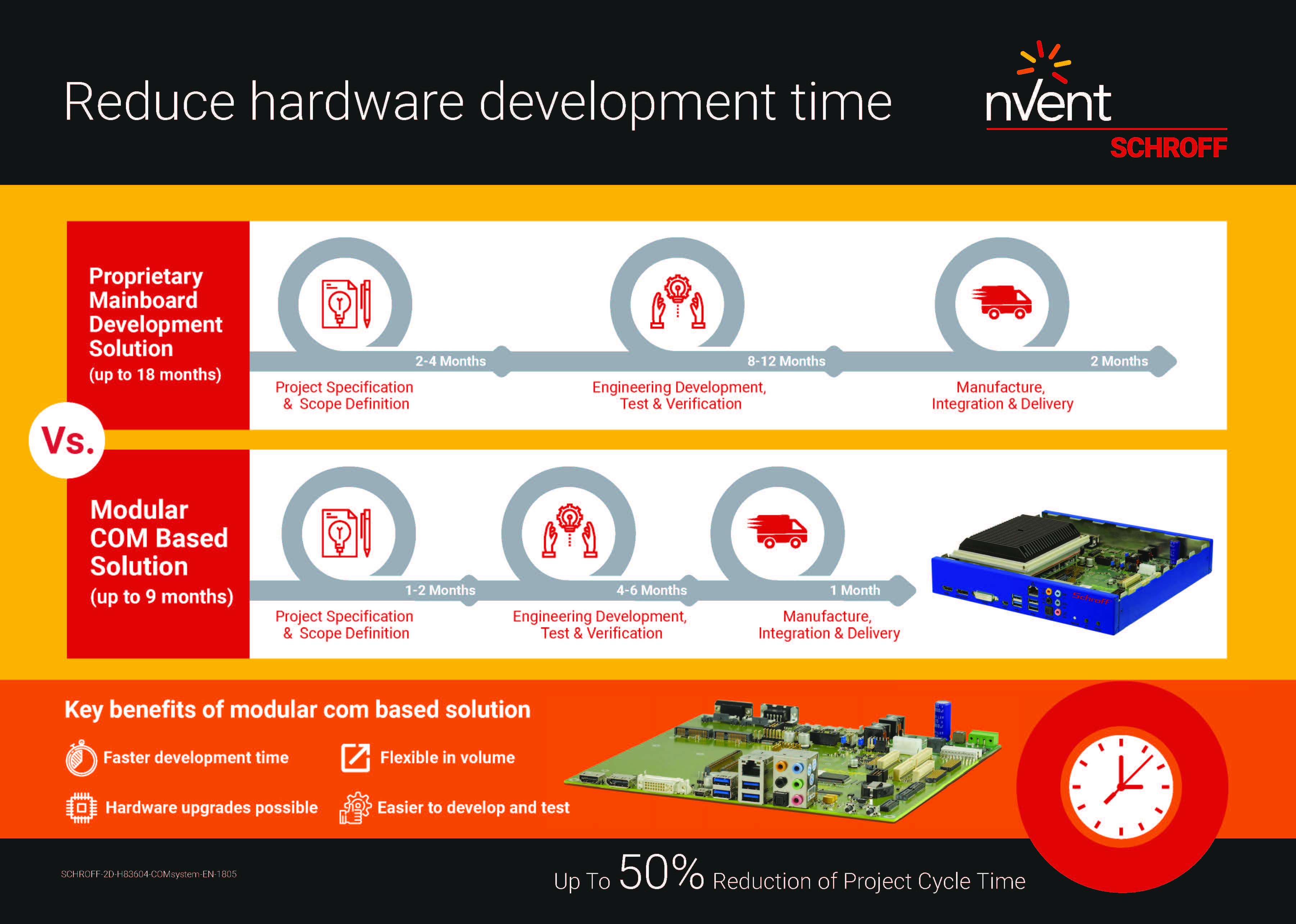

While a modular solution based on an off -the-shelf COM may not eliminate all the risks of lifecycle management, such an implementation can bring significant advantages. It will typically consist of a COM board (where the processor and most other shorter lifecycle components reside), a carrier board housing the COM and other I/O elements and the enclosure including case, cooling and power solutions. The carrier and enclosure portions typically carry a long enough lifecycle to satisfy end users, leaving the COM as the variable when chip upgrades occur. While COM boards are subject to the same component lifecycles as complete mainboard solutions, a new COM is easier to develop and test than a full mainboard. Also the COM can drop in to the existing embedded computer using the same connection interfaces as previous generations. As a result, hardware upgrades cost less, save time and resource demands while simplifying field repairs and upgrades.

Learn about selecting a COM based modular integrated system: download a free Ebook here!