Subracks, also known as card cages, are used for the reception of printed circuit boards (PCBs) and plug-in units (PIUs) in many different industries like telecom, transportation, test and measurement, aerospace and defense. For choosing the right subrack for your application, it is essential to be familiar with the fundamental requirements and standards. Check out seven criteria on how to select a subrack.

- Tip 1: Pay attention to Dimensions

- Tip 2: Comply with Standards and Specifications

- Tip 3: Be aware of Environmental Conditions

- Tip 4: Consider also Static and Dynamic Loads

- Tip 5: Don’t forget about EMC Shielding

- Tip 6: Design aspect – Underestimated, but very powerful

- Tip 7: Inform yourself about the Integration Levels offered

Tip 1: Pay attention to Dimensions

The size and type of electronics assemblies determine the dimensions of subracks. Also, the place of operation can lead to the need to meet certain specifications or restrictions.

Using the 19” standard

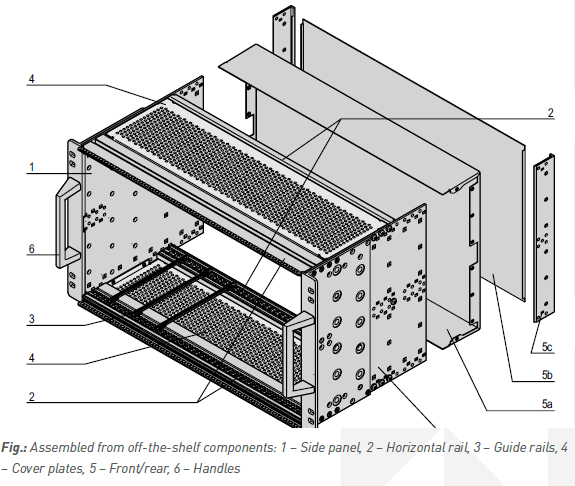

In general, we recommend the use of commercially available standardized boards that comply with the 19″ standard, as a large number of solutions are available according to these standards. Making use of off-the-shelf products saves the user development time, tooling costs, and no need to keep stock of specific components. Typical dimensions are 3 U and 6 U (height units: 1 U = 1¾ inches).

The downside of using “non-standard” components

For “non-standard” electronic components, such as non-standard printed circuit boards (PCBs), it is vital to ensure that the internal configuration of the subrack allows the inclusion of such non-standard components. If the electronics assemblies are small enough, frame type plug-in units provide compact solutions built into standardized subracks or cases. The external dimensions of the frame-type plug-in units are 19″ compatible and can accommodate both standardized and non-standardized electronic components. This allows non-standardized boards or components to be installed in a chassis or with a mounting plate in the subrack.

Trends influencing dimensions

Thanks to the ongoing miniaturization of components and the growing degree of integration, more than 70% of standardized boards are now produced in 3 U (Euroboard) format. This leads to a trend towards a reduction in the height dimensions of subracks. Another trend emerging is the increased use of active cooling of the boards with high heat dissipation losses using DC or AC blowers. To reduce the noise level during operation, intelligent blowers are becoming popular, which are controlled via system management.

Always consider the environmental conditions

The location where the system is finally installed naturally influences the dimensions of the subrack. Often the space available for installation – e.g., on ships or other vehicles or in data centers – is very limited, so the relevant specifications must be observed.

Tip 2: Comply with Standards and Specifications

Depending on the application, certain international and/or market-specific standards and specifications apply.

Commonly used IEC standards

Current standards contain additional dimension specifications (IEC 60297-1, IEC 60297-2, IEC 60297-3-101, IEC 60297-3-102, IEC 60297-3-103, IEC 61969-2-1, IEC 61969-2-2, IEC 60917-2-X) and – at a higher level – criteria for physical integration (IEC 61587-1, IEC 61969-3), earthquake resistance (IEC 61587-2), electromagnetic compatibility (IEC 61587-3), and thermal management (IEC 62194 Ed.1). The ETS standards were defined by ETSI (the European Telecommunication Standardization Institute). ETS standards are closely related to IEC standards, particularly in respect of European telecommunications systems.

Market-specific standards

In addition to IEC standards, there are specifications for specific market segments. For example, VME from VITA (VME International Trade Association) and CompactPCI, MicroTCA, and AdvancedTCA from PICMG (PCI International Computer Manufacturing Group). Also, there are particular standards and guidelines for applications in railroad or military technology, such as welding certifications (EN 15085), environmental tests (EN 50155) for railroad systems and shock and vibration testing (MIL 901D) for the navy, etc.

Protection and Safety standards

Also, special protection and safety standards must be considered, such as (to name a few).

- All conductive elements of a mechanical subrack that are capable of coming into contact with dangerous voltages must be grounded and tested to IEC 61010-1.

- The mechanical components of an assembly system should be free of sharp edges to prevent injury.

- The design and materials used for a subrack must also be appropriately selected to avoid the risk of fire.

- Plastics should conform to the self-extinguishing class as per UL 94 V 0 to V 2, tested to IEC 60707.

- Due to toxic additives contained in materials of the higher self-extinguishing classes, ISO 14000 must also be observed.

- IEC 60529 determines the IP protection classes against the ingress of dust or water and for the protection of persons from hazards inside the subrack. The IP protection class designation contains two digits. The first specifies the protection level against foreign objects (from contact by fingers to the ingress of dust), and the second indicates the protection against the ingress of water.

Tip 3: Be aware of Environmental Conditions

Other essential criteria in selecting a subrack are the physical forces acting on it and the level of electromagnetic shielding required. In measurement, instrumentation, and control systems, the requirements for shock and vibration resistance are generally not particularly high (up to 0 or 3 g). For applications ranging from traffic light control and industrial machine control to measuring systems for research or in accelerator rings, basic subracks are generally sufficient.

Often no EMC shielding is required, as this is provided, for example, by the cabinet in which the subrack is installed. If high deflection forces are expected due to the width of the unit and the heavy built-in parts, more robust designs are required.

Subracks for infrastructure applications, e.g., in passenger information or entertainment systems in railroad systems, on buses or aircraft, or as controllers for loading ramps, may in certain situations have to be shock and vibration resistant from > 5 to 25g. Loads of this kind also occur predominantly in defense systems, e.g., in controllers for target acquisition devices on ships. Applications for this particularly robust subrack include power generation for the control of wind turbines. In this case, the subrack is mounted in the nacelle of the windmill and the shock and vibration influences are similarly high. For these applications, the circuit boards mounted in the subracks are additionally secured with Card-Loks or Wedge-Loks.

Tip 4: Consider also Static and Dynamic Loads

The weight of the installed components is the main cause of static loads. This results in the choice of materials for the assembly system and the construction method – glued, welded or as a one-piece unit. Depending on the application, it may be necessary to fit additional reinforcements or stiffening elements. In the case of mobile use of a subrack, it is usually exposed to different dynamic loads. These different shock and vibration influences near the installation site must be taken into account, e.g., in the vicinity of rotating machines, in railway or traffic facilities, as well as on ships or aircraft. Seismic tests must be carried out prior to installation if the installation site is located in an earthquake zone.

Tip 5: Don’t forget about EMC Shielding

The electromagnetic shielding requirements of electronic devices vary depending on the application and environment in which they are used. This applies not only to high-frequency factors. Shielding is designed to cover electrostatic discharge issues and includes low-frequency capacitive or inductive coupling and cable-related faults, as well as high-frequency electromagnetic interference.

Side, top, and bottom plates, as well as the rear and front panels of subracks, are therefore provided with a conductive surface (passivated, etc.) and are conductively connected to each other via contacts such as stainless steel springs or textile EMC seals.

Each position of the cable entry must also be adequately protected. Standardized EMC tests (VG95373 Part 15) determine whether the EMC shielding measures meet the requirements of a specific application and ensure the reproducibility of this performance level.

The IEC 61587 environmental standard also defines tests for the EMC behavior of subracks. Section 3 of IEC 61587 outlines the test conditions for subracks in respect of their EMC shielding properties in the frequency range from 30 MHz to 21 GHz and the attenuation values.

The standard is mainly based on IEC 60297 and IEC 60917. To determine which degree of shielding is required, the critical interference frequencies must be identified. These tests are usually carried out by the manufacturer of the finished equipment or outsourced to independent external test centers.

Tip 6: Design aspect – Underestimated, but very powerful

Typically, the function primarily determines the appearance of a subrack and whether or not it is installed in an electronics cabinet. If the subrack is installed in the cabinet, the emphasis is clearly on functionality. But the front panel still plays a larger role in the visual design factor. Standard blank panels are available on the market in various sizes and versions.

But only a few manufacturers today have the necessary facilities to carry out individual designs and still efficiently produce panels. Some subrack manufacturers, such as nVent, offer complete service with a broad range of front panels offering paint or multi-color (also digital) printing options. This makes it easy for the customer to design an individual front panel, e.g., adding a logo.

Tip 7: Inform yourself about the Integration Levels offered

In addition to the basic mechanical assembly, demand for the integration of further components is increasing. At nVent, system integration includes electromechanical and electronic components such as EMC elements, cabling, switches, backplanes, power supply units, monitoring units, and cooling solutions, all in one subrack. As a result, users get a type of plug-and-play product for their 19” technology. nVent undertakes the entire project management and advises the customer from the initial specification and design, purchasing, prototype manufacture, testing, and checking right through to the actual product manufacture, including logistics and after-sales service.

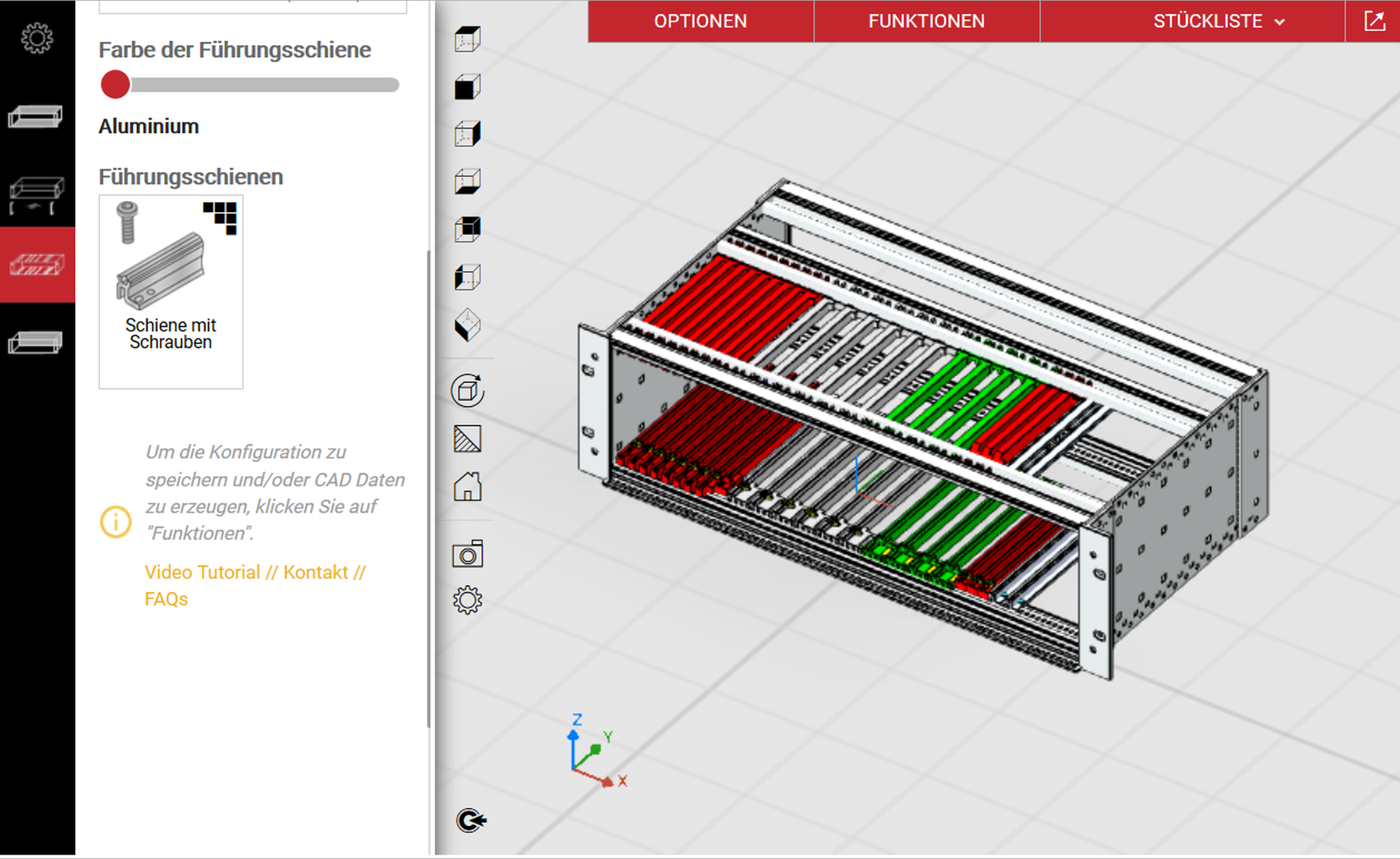

With the EuropacPRO subrack nVent SCHROFF is offering a flexible subrack platform based on the 19” form factor, with a wide variety of possible configurations and modifications.

Learn more here about our standard products from nVent SCHROFF; or configure your own subrack with a visual drag and drop configurator.