For grid-scale battery energy storage systems (BESS), grounding and bonding is essential for safety and performance. The goal of grounding and bonding is to achieve customer-targeted resistance levels. These low resistance levels allow fault currents to easily discharge into the ground, protecting people, equipment and the BESS itself.

The consequences of a failed or insufficient grounding system can be severe – thermal runaway leading to fires, system downtime, component failures, reduced efficiency and other safety hazards. A recent six-year audit by Clean Energy Associates found that over 25% of grid battery systems had manufacturing defects, putting them at high risk in these areas. The most common causes of defects were quality control issues from the assembly and installation of integrated systems, such as the grounding and bonding components. To help avoid these risks, it is essential to ensure system integrity by using a fully integrated, highly engineered grounding and bonding system.

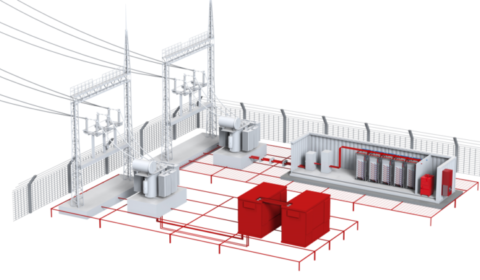

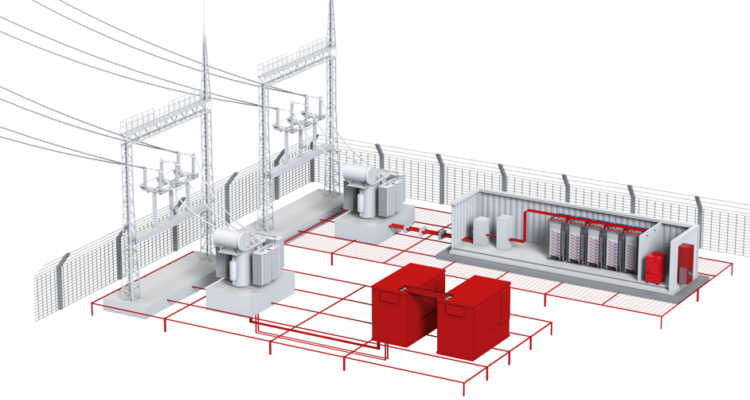

Total Site Electrical Protection

BESS developers and operators need robust, carefully designed grounding systems to prevent these issues and ensure a long service life for the infrastructure and equipment. High-quality, value-engineered grounding systems are key to meeting the desired BESS infrastructure service life of at least 25 years. Other solutions may meet these requirements initially but will degrade over time. nVent provides tested solutions that will deliver long-term consistent results.

There are complete grounding solutions for any situation, including:

- Traditional ground grids

- Floating ground grids

- Ufer systems integrated into concrete footers or helical piles

When installing a total grounding solution, including ground grids, working with an experienced partner is critical. Beyond a complete product offering, nVent can provide turnkey grounding design solutions through site evaluations, 3D modeling and detailed take-offs, ensuring a high degree of system compatibility, interconnection and functionality.

A reliable suite of grounding products is essential to a turnkey grounding system, including ground rods, grounding connections (compression, mechanical, exothermic), theft-deterrent grounding conductors, ground enhancement material, and cutting and crimping tools. This product offering contributes to the safety of people and personnel, as well as grid reliability. Using a single manufacturer for this total grounding system offers a higher degree of compatibility, interconnection and system functionality.

Another component of a total system is lightning protection solutions for BESS. nVent ERICO System 3000 is a cutting-edge solution for lightning protection, designed to provide optimized coverage with the proprietary nVent ERICO Dynasphere active air terminal. Utilizing the Collection Volume Method (CVM) strategically determines the ideal placement of air terminals based on detailed modeling of site-specific variables. This method eliminates unnecessary air terminals, distinguishing it from traditional systems like the rolling sphere method.

Notably, nVent ERICO System 3000 allows the customer to isolate the container in the event that there is inadequate bonding and grounding that could trigger a fire. System 3000’s design significantly lowers maintenance needs, making it a highly efficient and reliable lightning protection solution.

With the rise of grid-scale energy storage, proper grounding can no longer be an afterthought. It requires careful engineering from day one. Taking a proactive approach with grounding enables BESS operators to avoid downtimes, failures, and safety risks while maximizing performance and return on investment.

Learn more about nVent’s energy storage solutions here.