When constructing electrical protection systems, electrical grounding connections must remain dependable over the life of the system. If bonds weaken, grounding, bonding and lightning protection systems become susceptible to failures.

Exothermic welding, often known under by our brand name nVent ERICO Cadweld, is a method that has been around since 1938 and offers a number of advantages over other types of connections.

Discover what exothermic welding is, when it should be used and how it compares to mechanical grounding connections.

What Is Exothermic Welding?

Exothermic welding is a process used for joining similar metals, such as copper to steel or copper to copper. It employs an exothermic reaction to form a molecular bond between the two pieces.

The connection is produced in a purpose-designed graphite mold. The weld employs an exothermic reaction of thermite (powdered metal) to heat the metal. Put simply, the exothermic process involves a chemical reaction that releases heat and requires no external source of heat.

Exothermic Welding Chemical Reaction that Produces Heat

3Cu2O +2Al → 6Cu + Al2O3 + HEAT

Copper Oxide + Aluminum → Copper + Aluminum Oxide (Slag) + Heat

Reaction Temperature approximately 2500°C (4500°F)

When executed correctly, an exothermically welded connection is homogeneous after cooling, meaning a true weld has been formed and the elements are completely fused together. The connection is permanent, irreversible and requires no additional means to hold

it together, as shown in the image below.

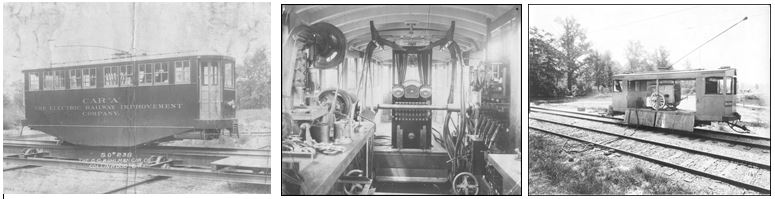

In the 1930s, Professor Charles A. “Pops” Cadwell, the namesake of nVent ERICO Cadweld, worked to improve the installation or repair of signal bonds and track power connections to electrified train rail. These welds took significant effort and equipment to complete. “Car A”, shown below, was used to transport the equipment and personnel needed to make a single connection.

In 1938, Pops patented the Cadweld process, and enabled one man with 25 pounds of equipment to replace all of this equipment previously needed. Shortly thereafter, exothermic welding for cathodic protection applications was created, followed by high voltage power transmission and electrical grounding and bonding connections.

Over the last 80 years, the equipment has been greatly enhanced to improve ease-of-use, product safety and weld quality to increasingly justify its use and broaden its applications. Exothermic welding is a significant invention that has accounted for more than 150 million connections.

How Does Exothermic Welding Compare to Mechanical Connections for Grounding?

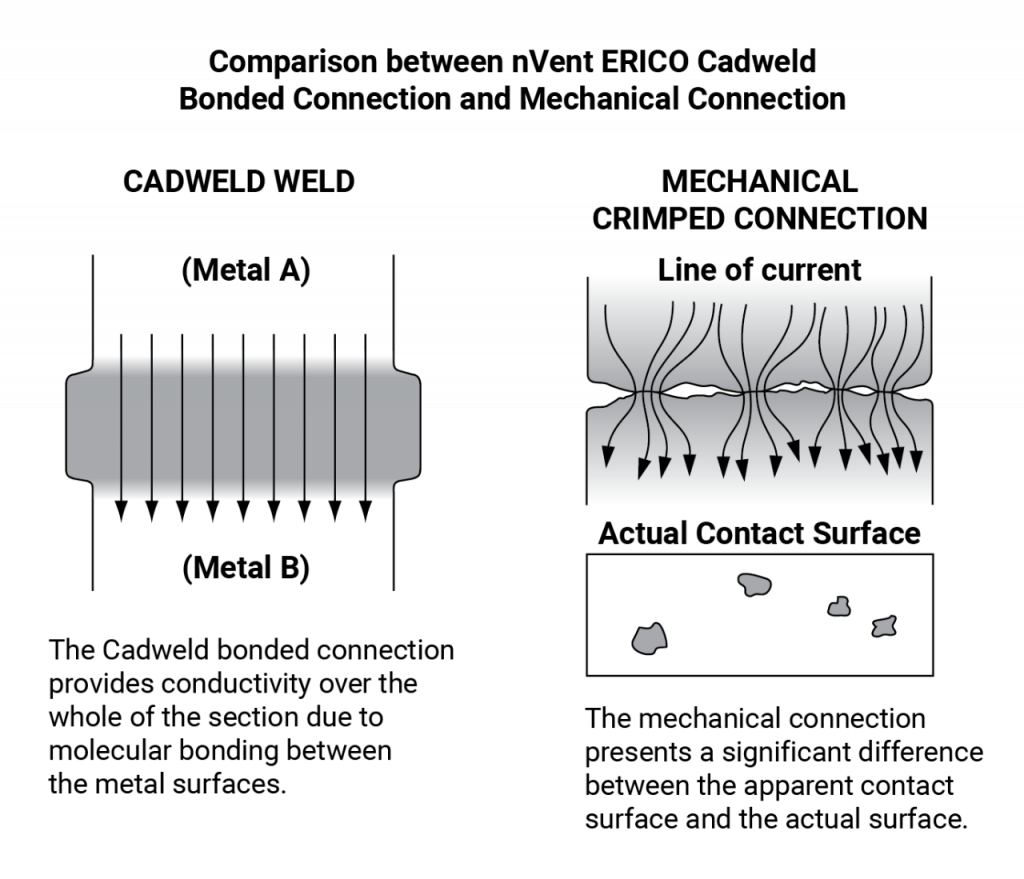

In general, exothermic connections are superior to mechanical connections for grounding due to the permanent bond made between two materials. Especially for use with electrical connections, a reliable connection is key.

Advantages of exothermically welded connections:

- Maintain a lower resistance over time due to the fused connection.

- Will not deteriorate with age due to a limited susceptibility to corrosion.

- Lifespan exceeds that of the conductors it connects.

- Eliminates any risk of loosening because of the molecular bonding.

- Will resist repeated faulty currents.

- Offers the lowest possible earth path resistance.

- Can be quality controlled by a visual inspection.

- Safe and easy to use with minimal training and protective requirements.

- UL® listed to UL 467.

- Exceeds the requirements of IEEE 837.

Disadvantages of mechanical connections:

- Cause a point-to-point current flow (i.e. unequal current density).

- Susceptible to corrosion, lowering resistance over time.

- Require an anti-oxidant compound in order to prolong the lifetime of the connection.

How Is an Exothermic Weld Performed?

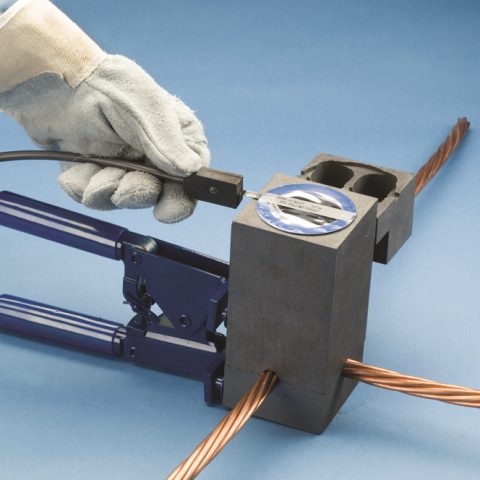

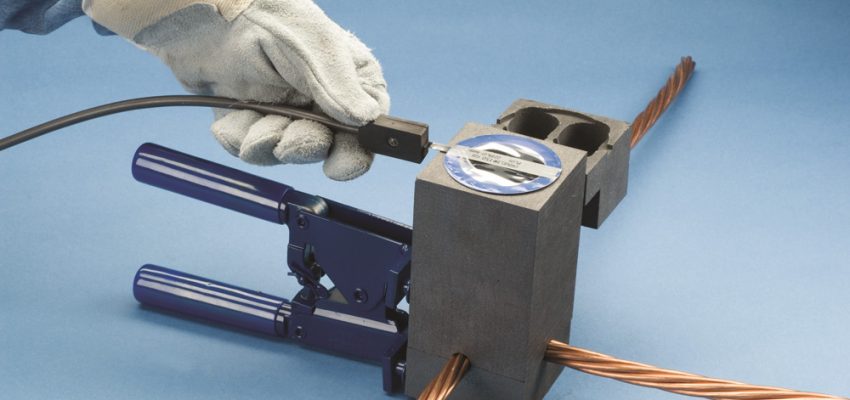

To illustrate the exothermic welding process, below are the directions using nVent ERICO Cadweld Plus.

Components:

- Graphite mold

- Weld metal

- Igniter

- Mold clamps

- Cleaning tools

- Sleeves, shims, batting

Directions for performing an exothermic weld:

- Insert Cadweld Plus cup into mold (may require use of a cover/baffle).

- Attach control unit termination clip to ignition strip.

- Press and hold control unit switch and wait for the ignition.

- Open the mold and remove the expended steel cup—no special disposal required.

After learning the process, it typically only takes a few minutes to complete an exothermic connection. Between the simple process and improved performance, exothermic welding becomes the preferred method for most electrical professionals.

Learn More About Exothermically Welded Connections

The value of exothermic connections is pretty clear. If you want to learn more about the specifying, installing or how to select the right Cadweld product and mold for your applications, click below to visit Cadweld.com.