Instrument winterization is crucial to keeping industrial facilities operating efficiently. Instrumentation measures process variables using a sensor that converts the measurement into a suitable signal and then transmits to a controller. Let’s learn more about this process, and how it can be implemented at your facility.

There are typically four common process variables of interest: pressure, temperature, flow and level. There are also analytic transmitters that analyze various chemical compositions. Instruments provide the signals that keep a plant operating safely. If the instrument is failing and cannot provide critical information back to the control room or DCS, a plant can shut down.

It’s essential to prepare for the Winter and ensure your instruments are winterized so that they do not fail at crucial times. This was illustrated when power plants in Texas and the US South East region were kicked offline during Winter Storm Uri, stopping crucial operations in their areas.

Instrument Winterization as Part of a Heat Management System

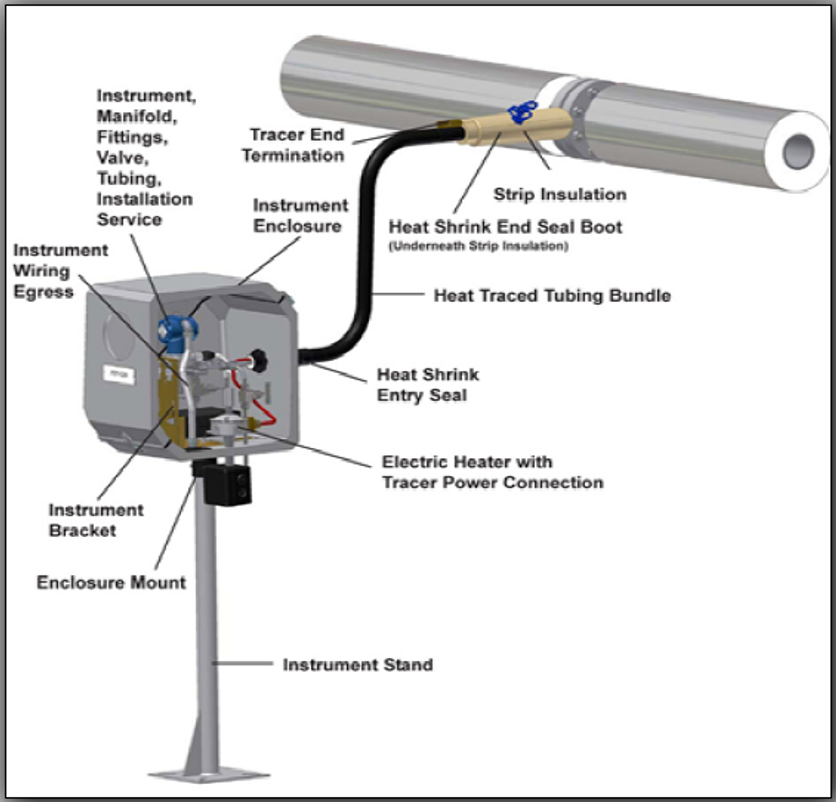

The inclusion of heating requirements for field-mounted instruments is an integral component of your overall heat management system. Incorporating the responsibility for the design and engineering of these systems assures that the heating technology, control and monitoring, and project controls are consistent with the overall heat tracing system.

A typical winterized instrumentation configuration will have the following components:

Common Applications for Heated Enclosures

- To prevent freezing

- PT, FT, DPT (differential pressure transmitters) typically have fluid filled manifolds

- To maintain a minimum operating temperature

- Analyzer or sample station enclosures for viscosity requirements

- Electronic instruments or computers are often not rated for below -25℃ (-13℉)

- Mechanical components such as valves, actuators, air compressors

The proper selection of winterization options involves input from multiple disciplines, including Process, Piping, Instrumentation, Electrical, and Operations. Managing these interfaces to maintain consistency between piping and equipment requirements and the unique requirements of instrumentation can reduce duplication of effort and associated cost.

nVent RAYCHEM and nVent TRACER are experts in providing heat management systems to ensure your equipment is winterized before the next freeze up. Want to learn more about Instrument Winterization? Join our upcoming live webinar on December 7th, 2021.

For more info, visit our MRO page and learn more about auditing your heat management system before winter kicks in.