When it comes to protecting your industrial facility against winter weather, it’s valuable to have tools at your disposal that help make the process easier. Let’s take a look at the basics of heat trace design using programs like TraceCalc Pro.

The Basics of Heat Trace Design

Electric heating cables maintain temperature of non-flowing fluids by replacing heat lost through thermal insulation on pipes, vessels and associated equipment. Insulation slows the loss of heat from the pipe, but does not stop it. This means insulation must be used on all heat traced systems or the heat generated by the cable will go to air, not the pipe. A reliable heat tracing design software can help you accurately design an electric heat traced system to protect your processes. Let’s look at TraceCalc Pro heat tracing design software from nVent RAYCHEM to help with winterization at your facility this year.

What is TraceCalc Pro?

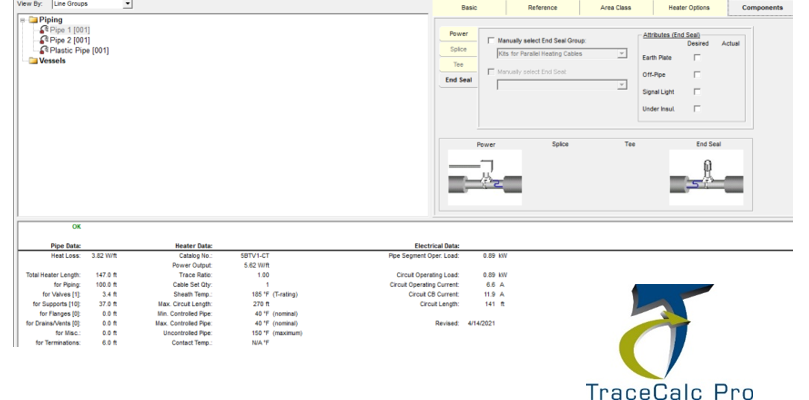

TraceCalc Pro is a powerful software that will guide you through step-step to design, calculate and specify reliable industrial heat tracing projects. It provides an intuitive, user friendly interface to create simple or complex designs for pipes, tanks and vessels. TraceCalc Pro allows users to access design data, including:

- Pipe heat loss

- Circuits

- Electrical Loads

- Sheath Temperatures

- And more

There are also advanced features, where users can explore:

- Multi-segment circuit designs

- Customized valve and insulation types

- Advanced editing features

When your design is complete, you’ll be able to produce a bill of materials (BOM) and various piping reports such as electrical line list, single line details and a summary line list report to start your heat tracing project.

In today’s industrial world, saving time can also mean saving money. With TraceCalc Pro, you can create an accurate heat trace system that will enhance productivity at your facility.

To learn more about how nVent RAYCHEM TraceCalc Pro, join our introductory webinar, Download the software here and start designing today.