Why Couplers? Advantages of Using Mechanical Splices

A recent trend shows that engineers are increasingly specifying mechanical coupler connections over traditional lap splices. Benefits of using mechanical couplers including reliability, consistency and proven longevity are a few of the reasons why. Learn more here about the basics of mechanical couplers, as well as the benefits of using these systems.

Traditional Rebar splices

Traditional connection methods for reinforcement were to overlap two parallel bars, with the overlap load transfer mechanism taking advantage of the “bond” between the steel and concrete. The load in one bar is transferred to the concrete and then from the concrete to the ongoing bar. The “bond” is largely influenced by the deformations (transverse ribs) on the surface of the reinforcing bar.

Many considerations should be made in the design of a correctly engineered overlap splice, including:

- Grade of steel

- Surface condition of the bar

- Size of bars

- Grade of concrete

- Position of the splice with respect to concreting

- Design loads

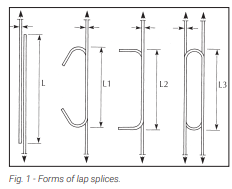

Examples of Connection Types

A traditional lap with installation options to reduce the lap length “L” with bent reinforcement are shown below, though these means are expensive and cannot be used in all cases.

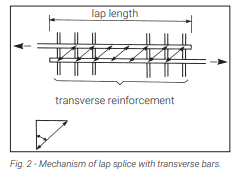

Fig. 2 shows how the overlap transfer mechanism generates additional forces in the concrete. These forces tend to push the bars apart and the concrete cover must be strong enough to sustain this “bursting” force. Should the bursting force become too large then “spalling” of the concrete cover will occur and the splice fails. Most design codes require additional transverse reinforcement especially for splices of larger sizes of reinforcing bars.

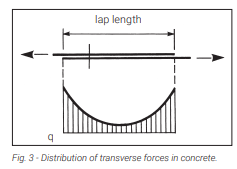

The diagram below illustrates the distribution of tensile stresses in the concrete normal to the axis of the bars. (The steel bars may be in either axial tension or axial compression.)

For full details about the above graphics, view our full “Why Couplers?” resource.

Mechanical Splices are Proven, Strong and Reliable

Mechanical connections offer greater structural integrity, which is important for the safety of those in and around the building. These connections are also more reliable than the lap systems because they do not depend on the concrete for load transfer. Mechanical splices also allow structural designers to achieve an ideal balance of steel and concrete by eliminating the additional rebar lap zone, meeting building code requirements in many areas.

Another benefit of mechanical splicing is reducing the rebar congestion on a job, by decreasing the rebar in the lap zone and simplifying bar placement, which also helps to decrease the possibility of pockets and voids in the concrete. Coupler systems can allow for improved concrete flow, as well as overall flexibility in design options. These benefits will also help to accelerate job schedules, keeping projects on-budget and on-schedule.

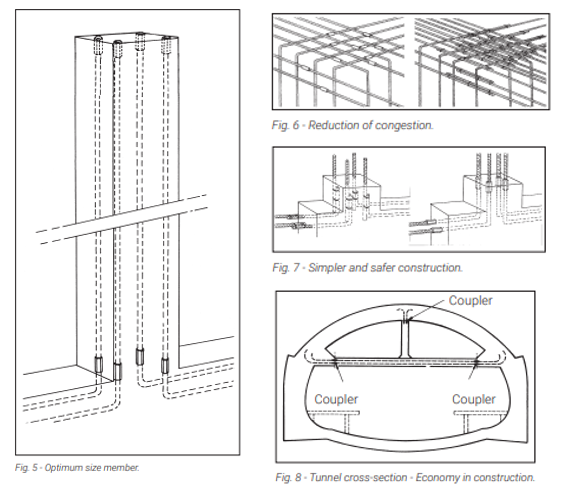

Fig. 5-8 shows various applications where mechanical splices are used to great technical and economic advantage – simplified design and execution – improved robustness and durability – reduced cost.

Want to learn more about mechanical coupler systems? Contact our nVent LENTON sales representatives today.