Anyone who has watched a new building go up in their neighborhood knows construction can be a time-consuming process. With this in mind, it’s easy to imagine the complexity of building a large, high-tech manufacturing facility on a tight deadline.

This is the challenge one of nVent’s European customers faced. Midland Steel Reinforcement Supplies, a cut and bend reinforcement manufacturer in Ireland and the United Kingdom, was tasked with supporting a new facility construction on a tight timeline, with little room for error.

Labor-Saving Solutions

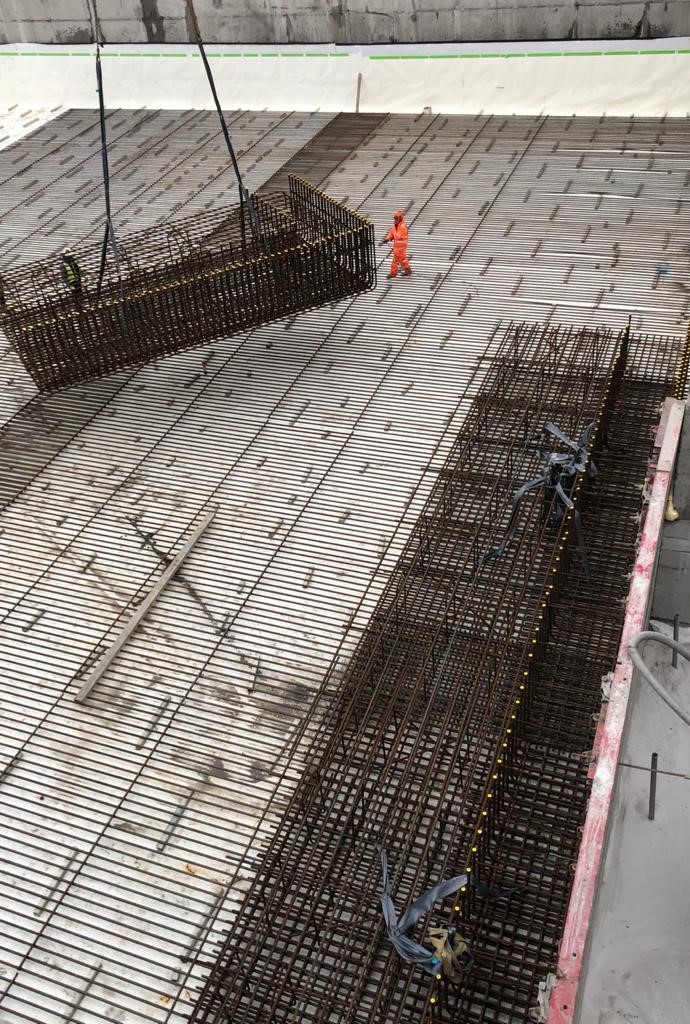

In precast and prefab construction processes (see “Modular Construction” below) workers build sections of buildings—either rebar cages or entire poured concrete sections—in a controlled factory environment, saving significant time by increasing the quality and speed of construction by limiting site setbacks or inclement weather delays. However, once built, precast and prefab sections of buildings must be connected at the site quickly, efficiently and providing full load transfer between the elements to ensure the integrity of the finished structure.

In precast and prefab construction processes (see “Modular Construction” below) workers build sections of buildings—either rebar cages or entire poured concrete sections—in a controlled factory environment, saving significant time by increasing the quality and speed of construction by limiting site setbacks or inclement weather delays. However, once built, precast and prefab sections of buildings must be connected at the site quickly, efficiently and providing full load transfer between the elements to ensure the integrity of the finished structure.

Midland Steel supplied reinforcement for the entire construction project, including loose rebar and prefabricated cages for both the job site and the precast facility. Midland Steel needed to ensure workers could assemble precast and prefabricated sections quickly, easily and reliably, and looked to nVent to provide a connecting solution.

Normally, when rebar fits together, workers tighten the connection between bars by rotating each end into a coupler, similar to tightening a screw. However, in prefabricated and precast construction, bars may already be set into structures weighing many tons; therefore, workers need to be able to tighten the connections without rotating the bars. In this case nVent LENTON position or Interlok couplers can be used to connect rebar.

Essential Connections

To meet the demands of this challenging project, nVent provided Midland Steel a wide range of standard couplers, position couplers and mechanical anchors: nVent LENTON A12N, P13LN, P14LN, D14N and D16N variant couplers. These products all share two important features: self-alignment and a minimal number of turns required for installation.

While standard coupling systems typically need 10-12 turns to install, nVent LENTON couplers only require approximately 4.5 turns. Although a few extra turns on a single coupler may not seem like a lot of additional effort, Midland Steel’s customer installed over 30,000 coupler connections on the facility job site. Overall, the prefabrication process combined with the coupler technology of nVent LENTON products helped Midland Steel eliminate approximately 150,000 extra bar and coupler rotations and decreased onsite labor time by 80 percent.

While standard coupling systems typically need 10-12 turns to install, nVent LENTON couplers only require approximately 4.5 turns. Although a few extra turns on a single coupler may not seem like a lot of additional effort, Midland Steel’s customer installed over 30,000 coupler connections on the facility job site. Overall, the prefabrication process combined with the coupler technology of nVent LENTON products helped Midland Steel eliminate approximately 150,000 extra bar and coupler rotations and decreased onsite labor time by 80 percent.

Additionally, using nVent LENTON taper threaded couplers helps to prevent cross-threading, which can result in misaligned rebar and coupler connections. When a worker starts to rotate the bars or couplers to form connections between pieces of rebar, the nVent LENTON taper thread automatically draws the pieces into the correct alignment, making construction quicker and easier while greatly reducing error. For large projects like Midland Steel’s, ease of installation is a major benefit when connecting structures weighing several tons.

“Using their innovation and concrete experience, the versatility of nVent LENTON couplers from A12 to P-Type allowed the majority of the project to be designed using couplers—from the connection in precast columns to the connections on some very deep waffle slab—saving time and saving cost on steel,” said Tony Woods, managing director of Midland Steel Reinforcement Supplies.

Finding the right solution for the customer’s coupler needs ultimately benefited all parties. Midland Steel and the site construction teams were able to stay on schedule and the facility opened without delay. Although the nVent LENTON products are now set in concrete and out of sight, they will continue to provide essential, structural connections for the life of the new facility.

What Is Modular Construction?

In traditional construction, workers assemble cages at job sites out of loose reinforcing bars (rebar). However, these reinforcement cages can also be assembled offsite—a process called prefabrication, or “prefab,” such as the FasterFix solution offered by Midland Steel. When the cages arrive prebuilt, workers can immediately lift the cages into place which speeds up the start of concrete pours and saves time that would otherwise be spent on assembling cages.

In traditional construction, workers assemble cages at job sites out of loose reinforcing bars (rebar). However, these reinforcement cages can also be assembled offsite—a process called prefabrication, or “prefab,” such as the FasterFix solution offered by Midland Steel. When the cages arrive prebuilt, workers can immediately lift the cages into place which speeds up the start of concrete pours and saves time that would otherwise be spent on assembling cages.

In some circumstances, construction teams opt for “precast concrete.” In precasting operations, workers pour concrete onto reinforcement cages at a facility away from the job site to produce completed building sections, such as a column, beam or wall panel. The completed sections are then transported to the job site for on-site installation, where workers lock the precast sections together using couplers to provide structural connections between the rebar cages cast into the concrete.

Prefabrication and precasting are both a part of the modular construction process. Modular construction can reduce waste, save time and create added safety for workers since assembly takes place in a controlled environment. The global market for modular construction is on the rise as the technology improves and companies continue to realize its benefits.