In the previous blog post covering the seismic webinar in 2019, we covered the earthquake basics, codes and standards, and when to brace. This post will cover the applications to brace in with examples and what products can be used to properly brace to code.

There are a few solutions for how to properly brace mechanical, electrical, plumbing, fire and HVAC services, including rigid bracing, cable bracing, branch line restraint systems and rod stiffeners. More specifically, a full solution can be engineered from single pipes and conduit, to trapeze, to distributed systems and suspended equipment.

Seismic Bracing Product Categories

Single Pipes and Conduit Braces

Single pipe and conduit rigid and cable braces protect fire sprinkler systems, gas piping systems, electrical conduits and plumbing systems. The rigid bracing solutions braces pipes 1” through 12” and the cable brace is unlimited. These seismic bracing solutions include easy-to-install and easy-to-inspect snap-off bolts, with only one wrench needed for installation.

Industry Standards: Meet requirements of NFPA® 13; are cULus® Listed; rigid braces are FM® Approved; OSPHD Pre-Approval of Manufacturer’s Certificate (OPM)

Trapeze and Threaded Rod Braces

Trapeze and threaded rod braces are used to brace trapezes, distributed systems and suspended equipment. These products brace rods 3/8” through 3/4”, and have retrofit ability which allows for the brace to be installed after the trapeze assembly is installed. One size wrench is needed for installation of the rigid bracing products, and the shear-off head ensures correct torque, simplifying inspection.

Industry Standards: FM® specifications tested; OSPHD Pre-Approval of Manufacturer’s Certificate (OPM)

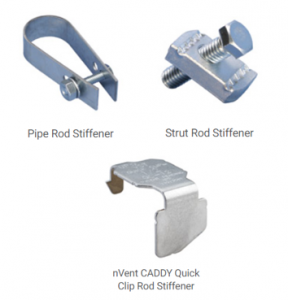

Threaded Rod Stiffeners

Threaded rod stiffeners are used to protect threaded rods from buckling in compression, and can brace rods 3/8” through 7/8”. The nVent CADDY Quick Clip Rod Stiffener enables one hand, snap-in installation, with no tools or bolt tightening required. These products use the nVent CADDY Seismic Bracing Calculator to calculate the requirement and spacing project-by-project.

Industry Standards: OSPHD Pre-Approval of Manufacturer’s Certificate (OPM)

Structural Attachments

Structural attachments can be used for installation of trapezes, distributed systems and suspended equipment to steel, concrete or wood. They can be used with anchor holes sizes 1/2” through 3/4″, and use one size wrench for installation with shear-off heads for correct torque. The no-pry clip product option provides a no-prying effect option in concrete installations.

Industry Standards: Meet requirements of NFPA® 13; are cULus® Listed; FM® Approved or Specification Tested; OSPHD Pre-Approval of Manufacturer’s Certificate (OPM) or pending

Pyramid Rooftop Anchor System

The nVent CADDY Pyramid Rooftop Anchor System is important for rooftop electrical and mechanical equipment, especially in seismically active markets or those at risk for high winds. The rooftop anchor system fastens directly to the roof desk, creating a permanently sealed anchor. The system preserves membrane manufacturers’ warranties, as minimal roof membrane penetration is needed when installed correctly. The system also eliminates the ballasting needed, reducing weight on the roof structure. nVent CADDY offers a total roof solution when combined with additional nVent CADDY Pyramid products, and design and engineering services are available for complete layouts and more.

To view the variety of solutions for seismic bracing available from nVent CADDY, visit our product page.

Want to listen to the webinar in full or download the slides? Visit our site.