This is the third article in our series on our Products pillar ESG categories. If you haven’t already, go back and read our first two entries on Eco-Friendly Designs and Eco-Friendly Materials. The first article will also give you additional context on why our Products pillar ESG categories are important and how we put them into practice in our New Product Introduction process.

In this piece we are discussing End-User Safety.

Safety is a critical part of who we are at nVent. Our focus on safety extends from how we produce our products and solutions to the safety of our customers who put those products into use. We develop easy-to-use products that improve end-user safety and experience and help our customers improve the safety of their operations by facilitating uptime and resilience for critical systems.

When we think about End-User Safety, ease of use is critical. Easier handling and transportation and toolless or reduced tool installation can both drive end-user safety, as can low risk installation methods that eliminate or reduce time spent on ladders and lifts. We can also help eliminate potentially unsafe tasks for workers; for our customers in manufacturing, our automation solutions can quickly and easily perform processes like panel and wire cutting that could be risky for workers.

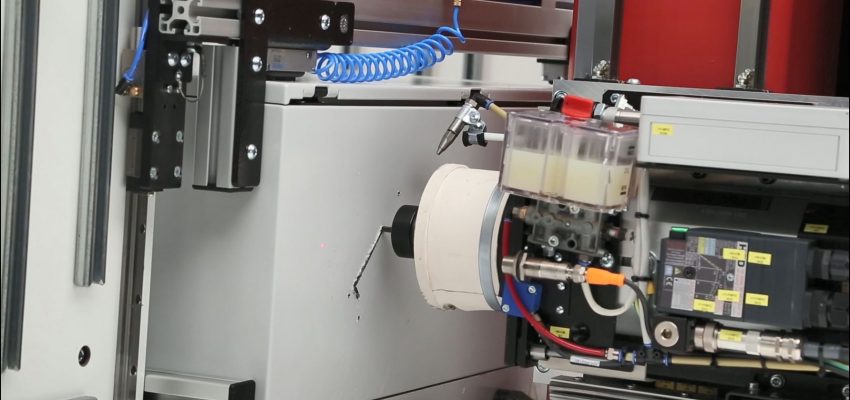

For example, our Personal Wiring Assistant performs wire cutting, stripping and connector crimping, preventing the possibility of fatigue or injury to a person performing these repetitive tasks. The personal wiring assistant can cut, strip and connect over 100 wires in an hour. Another example is the nVent HOFFMAN ModCenter, one of the most versatile automated enclosures modification solutions available today. It enables fast modification of stocked enclosures and panels for quick shipping, facilitating machining of various materials including mild steel, stainless steel, copper, aluminum, fiberglass and thermoplastics. The ModCenter eliminates the need for workers to perform the potentially dangerous work of cutting enclosures.

Another example is our nVent CADDY Rod Lock product platform, which allows contractors to prefabricate complex hanging assemblies needed for the installation of conduit, cable tray, lights, ductwork and pipe systems on the ground, then easily lift and lock them into place by pushing threaded rod supports into the nVent CADDY Rod Lock device. This makes installation faster, easier and more secure. Our new push-to-install spring steel strut nuts offer 60% faster installation for prefabricated cable management trapeze systems and 71% faster installation when hanging enclosures. Faster and easier installation time allows contractors to spend less time on ladders or overhead, contributing to increased safety and less fatigue.

Our products also contribute to safety on a larger scale, helping to keep critical infrastructure operational during emergencies and protecting buildings and infrastructure from threats like lightning and seismic events. Safety is at the core of what we do at nVent. By designing and building solutions that drive safety for our end users, we are contributing to our vision of a safer and more secure world.