Out of sight, out of mind.

That’s the way most people look at building system components located on rooftops. While this equipment can be essential to the operation of the building—controlling HVAC, electrical and other systems—it’s easy to forget about it. Even less attention is given to pipes, ductwork, elevated walkways and other functional components up there… until something goes wrong.

While rooftop equipment and components are generally built to resist the elements, that doesn’t mean they’re ready to handle anything that Mother Nature might throw their way. It’s a fact of which we’re reminded as we’re currently in the middle of hurricane season, with related and unrelated severe storms impacting parts of North America. We learned that recent earthquakes near Ridgecrest, California, may not have been “catastrophic” but still caused an estimated $200 million in damage.

Creating Stability Where It Matters Most

The exertion of significant weather events on rooftop equipment and components is problematic for a couple of reasons.

First, and the most obvious, is that equipment can be damaged, yielding repair costs. If an elevated walkway is damaged or blown over, a pipe or duct is ruptured, or a piece of flying debris slams into an electrical cabinet or air conditioning unit, your facility operations can quickly be crippled. According to the Federal Emergency Management Agency (FEMA), damage to rooftop equipment is prevalent during high-wind events, so this is far from an uncommon occurrence. They also point out the danger of loose equipment becoming detached and creating a hazard of their own as airborne debris.

Then there’s the risk to the waterproofing membrane installed across your rooftops to protect the inside of the building from water damage (an especially daunting concern in severe storm situations). The efficacy of rooftop waterproofing is contingent on maintaining a monolithic barrier against moisture infiltration, and any penetrations of the membrane can cause major water damage issues. If rooftop equipment and components are displaced during severe weather events or intense seismic activity, they can easily create tears in the membrane or damage sublayers of the roof.

You can’t stop a natural disaster, but you can minimize your risk of these types of damage by taking steps to secure your rooftop equipment and system components with specialized anchoring and support systems. Some designs are better than others at protecting both your equipment and your waterproofing layers. Let’s take a look at the nVent CADDY Pyramid Anchoring System as an example to give you an idea of how they work.

Rooftop Anchoring: Defense Against Environmental Damage

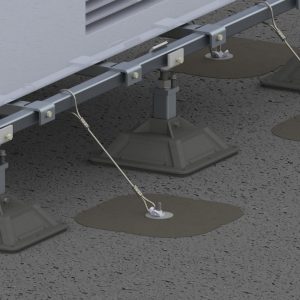

The nVent CADDY Pyramid Anchoring System is comprised of three main elements:

- nVent CADDY Pyramid Anchors: These flat, watertight, membrane-matching rooftop anchors are attached to the roof deck and are sealed to the roofing membrane. The anchors can be matched to the roofing material membrane to prevent water infiltration, maintain a clean look and preserve the membrane manufacturer’s warranty (which not all anchors do). You only need simple, common tools to attach the membrane patch to the existing waterproofing membrane.

- nVent CADDY Pyramid Roof Supports: These surface-mounted structures elevate and support electrical and mechanical equipment, not only keeping said equipment stable, but distributing weight evenly to limit pressure on the rooftop (which can be multiplied when there are high winds or tremors). Foam or rubber bottoms on the feet of the support structures minimize risk of membrane tearing, and these support systems are compatible with any roofing membrane type.

- nVent CADDY Pyramid Rooftop Cable Bracing: Stainless-steel cables are attached from rooftop equipment directly to the roof deck, anchoring the equipment firmly in place. The stainless-steel cable composition resists corrosion well, and the cables’ flexibility allows them to be attached to any type of equipment or accessory. The cable bracing kits come with pre-installed hardware to ensure proper secureness of the rooftop elements to the anchors while providing flexibility to any type of installation. Stainless-steel cables provide durability for harsh rooftop environments.

When you combine components of the pyramid product line together, the result is an anchoring system that can hold anything from HVAC units and heavy-duty mechanical equipment to piping in place, limiting the risk of costly damages in the face of elemental forces. Systems can be customized depending on the type of equipment or components that need to be held in place, the type of roofing membrane and other considerations. This bracing method is an ideal alternative to ballasting or station style systems.

Whether a roofing anchor system is right for you depends on your operating environment, amount of equipment on your rooftops and appetite for risk. What’s important is realizing it’s an option if you’re looking to protect yourself from non-cataclysmic but still costly weather-related damage.

Want to learn more about roofing anchor systems? Read about them here, or contact us.